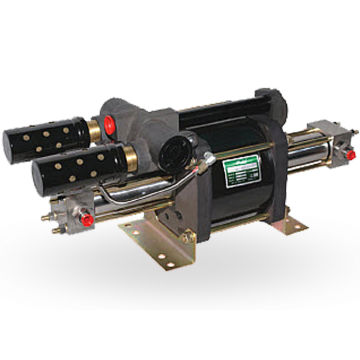

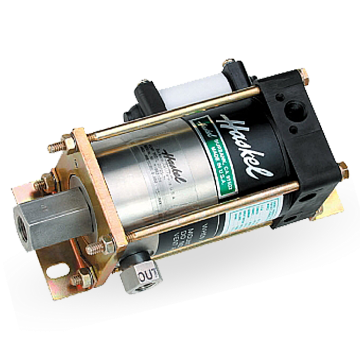

Description

A low cost, reliable means of generating and sustaining static medium to high-pressures.

For over 75 years, Haskel has been the leading name in pneumatic-driven liquid pumps. Haskel’s pneumatic pumps are designed to provide a safe, reliable, and economical source of hydraulic pressure.

A Haskel hydrostatic pneumatic pump’s robust design will efficiently convert compressed air into hydraulic power, satisfying any application need for pressurizing up a component and holding it at a set pressure for any sustained period of time.

Backed by a global network of high-pressure expertise, service and support, our pneumatic pumps are consistently recognized as the most reliable in the industry.

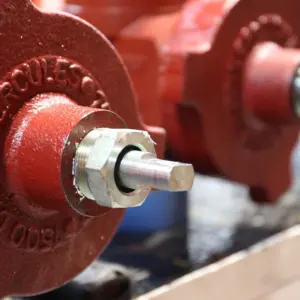

The hydrostatic pumps automatically reciprocate on a differential piston principle. A large

piston driven by relatively low pressure drive acts directly upon a smaller hydraulic piston.

The nominal ratio between piston sizes is indicated in the model coding and approximates to the maximum working pressure. The actual ratio is about 15% above nominal so that the pump continues to cycle when drive pressure

equals nominal ratio. Initially, the pump will cycle at maximum speed acting as a transfer pump to pressurize downstream.

It will cycle at a slower rate as the fluid meets resistance until it stalls at maximum output pressure. When a pressure drop downstream occurs, it will recycle as necessary in an

effort to maintain maximum pressure.

Stall pressure is achieved when the outlet pressure rises and offers more resistance to the reciprocating differential piston assembly. The piston assembly then stalls when the forces

balance, e.g. when drive pressure x drive piston area equals outlet (stall) pressure

x driven hydraulic plunger area. The pump design is sensitive to very small pressure drops due to the low frictional resistance of the large diameter drive

piston and hydraulic piston seals.

Proven to be safe, robust, reliable, compact, and easy to maintain, Haskel pneumatic-driven liquid pumps provide a number of operational benefits:

- Safe pneumatic operation – no heat, flame or spark risk

- Up to 100,000 psi (7000 bar) capability

- ATEX certified

- Infinitely variable cycling speed

- Stall feature at pre-determined pressure to hold that pressure without consuming power

- Problem-free stop/start applications

- Easily automated, with many modification and control options available

- Suitable for most liquids and liquefied gases

- No need for air-line lubrication, which saves costs and prevents contamination

Application

- Bolt Tensioning

- Brake Application

- Calibration

- Component flush

- Controlled force, paper mills

- Clamping

- Crimping

- Cutting

- Cylinder Testing – DOT

- Down Hole upstream pressure equalization

- Flange spreaders

- Fluid charging

- Gun turret leveling

- Hydraulic power unit

- Hydraulic Cylinder Actuation

- Isostatic Pressing

- Jacking and lifting

- LPG reclaim

- Lubricating

- Machine counter balance

- Mechanical seal pressurization – barrier fluids

- Metal forming/Hydraulic forming

- Methanol Injection

- Oil Injection for bearing removal

- Packer inflation

- Power pressing

- Press Safety Overload

- Pressure Testing

- Proof testing components

- Positioning cylinders

- Relief valve testing and setting

- Roller Tensioning

- Sampling

- Silicon chip Cleaning (washing machine)

- Swaging

- Testing and operating downhole equipment

- Valve actuation

- Vehicle safety braking

- Water Jet cutting – low density

- Wellhead control

- Work holding