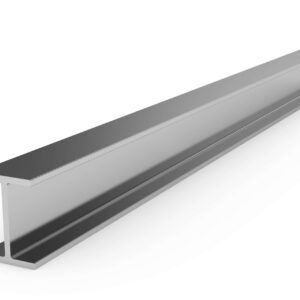

Description

The Conductor Pipe is a large diameter pipe that is set into the ground to provide the initial stable structural foundation for a borehole or oil well.

It can also be referred to as a drive pipe because it is often driven into the ground with a pile driver.

Conductor pipe is typically set, on petroleum wells, before any drilling operations are performed. It is usually set with special pile-driving or spudder rigs, though the drilling rig is sometimes used to save time and money.

In the offshore drilling industry, the conductor pipe is set in the seabed, and is a key structural foundation for the subsea wellhead. When drilling an offshore well, a marine riser is connected to the well, and this is subjected to large environmental forces such as current and waves which are transferred to the conductor. The forces can be large and also cyclical which can potentially cause fatigue damage to the conductor, especially in harsh environmental conditions. A Conductor tensioner unit (CTU) can be used in shallow water on jackup rig to withstand such damaging forces.

Specification

Sizes

Outside Diameter (Inches) 18 to 42

Grades

B, X42, X46, X52, X56, X60, X70

Type of Welding Process

ERW (Electric Resistance Weld), SAW (Submerged Arc Weld) , DSAW (Double Submerged Arc Weld)

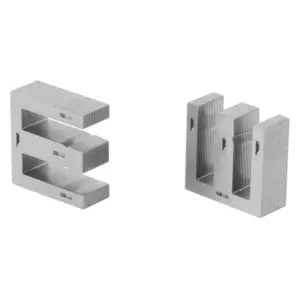

Connections

Plain End or welded with connectors according to your requirements.